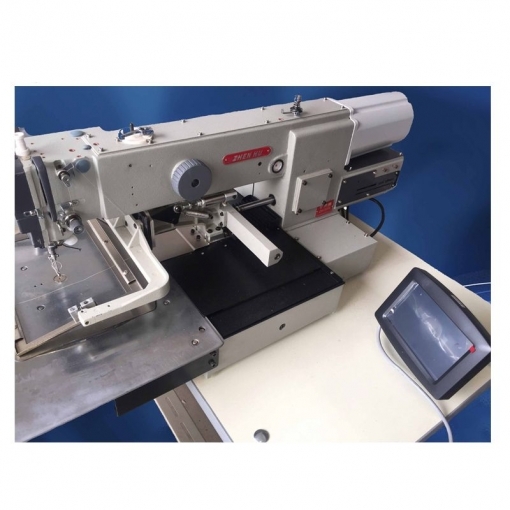

Computerized pattern sewing machine for belt making

Model Number: ZH3020/ZH6040| Applicable Industries | Manufacturing Plant |

|---|---|

| Type | Industrial Sewing Machine |

| Stitch Formation | Lock Stitch |

| Mechanical Configuration | Post-Bed |

| Max. Sewing Thickness | Medium |

| Stitch Length | 10-38mm |

| Power | 220V/550W |

| Overall Dimensions | 127*105*132cm |

| Feed Mechanism | Multiple |

| Weight | 200 KG |

| Working area | 30x20cm |

| Function | Computerized pattern sewing |

Computerized Pattern sewing machine, shoe upper and bags embossing machine

Application & Specification

1. This kind of sewing machine can help companies save manpower, reduce wastage , improve quality, increase productivity, improve the company's customer satisfaction, in order to achieve the objective of improve the company's core competitiveness.

2. Movable and reversal presser to act as " robotic arm" for sewing faster and avoiding getting workers hurt.

3. With automatic parking, automatic thread trimmer, automatic pine line, auto-dial line, automatic presser foot and other functions, easy operation. Regardless of how complex patterns can be a one-time perfect sewing, anyone skilled to operate the machines in a very short period of time.

| No. | Typre of controller | Computerized control system pattern-sewing machine |

| 1 | Sewing area | X(Lateral)direction Y(Longitudinal)Direction 300(mm) x 200(mm) |

| 2 | Max sewing speed | 2500rpm |

| 3 | Stitch length | 0.1~12.7mm |

| 4 | Feed motion of frame | Intermittent feeding (2-shaft driven by pulse motor) |

| 5 | Needle bar stroke | 41.2mm |

| 6 | Needles | DPx5, DPx17 |

| 7 | Lift of frame | Standard 18mm to max 22mm |

| 8 | Intermediate presser | stepping driving(range: 0~8mm) |

| 9 | Lift of intermediate presser | 20mm |

| 10 | Rotating shuttle | Double-capacity semi-rotary hook |

| 11 | Memory of pattern data | Memory/U disk |

| 12 | Operation temperature range | 0℃~45℃ |

| 13 | Sewing machine motor | Servo motor |